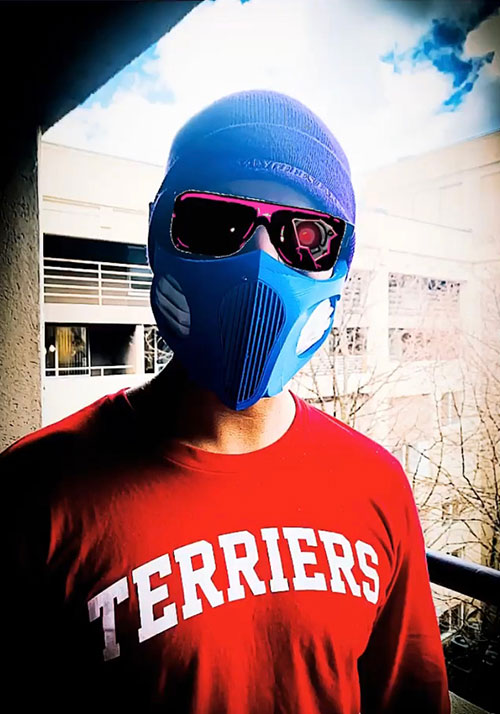

As the COVID-19 pandemic pushed us to social confinement, closing colleges and works, and living us with some extra time, I decided to take advantage and hone my 3D printing skills. The following mask is a design taken from Thingiverse. I wanted to improve the time it takes to print this mask by reducing the infill and changing the support structure while maintaining proper functionality.

As a result, for this mask, although printing time is reduced by setting the infill to 0%, the mask becomes very fragile when removing from the heated bed. In my experience, the plastic adhered too much to the tape on the bed and when I removed the printing it felt as if it was about to break.

In terms of the supports, I have been testing three supports. I set them to only touch the bed, and as the print raises the supports never touch the part which makes it easier and cleaner for after processing.

In the future, I would try to set different infills for the supports and the actual part. My current setting assumes the same infill for both, and as the mask was being printed it seemed the supports would break eventually because they were hallowed and fragile.