DESIGN AND MANUFACTURE OF A CALCULATOR HOLDE

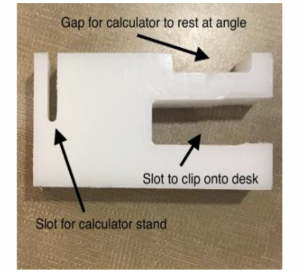

Classroom desks are not large enough to fit all of the supplies engineering students need during classes and exams. A portable calculator holder that clips onto any desk, providing a designated spot for bulky calculators to go and saves precious desk space during class and exams.

Collaborators: Adrian Perez, Darwin Chiu, Nicole Zarillo, Matthew Averill.

Parts Specifications

•Desk Clip: 3” x 1.5” x .75” Thick enough to support calculator and clip onto desk.

•Calculator Stand: 3” x 1.5” x .25” Ideal height for a calculator.

•Additional 0.05” tolerances so the robot has more room for error during assembly.

•Parts designed using PTC-CREO and GibbsCAM

HDPE Desk Clip

Polycarbonate Stand

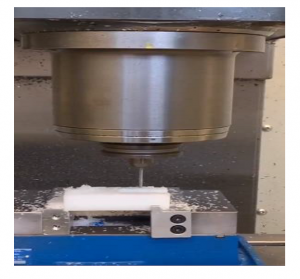

Manufacturing Processes

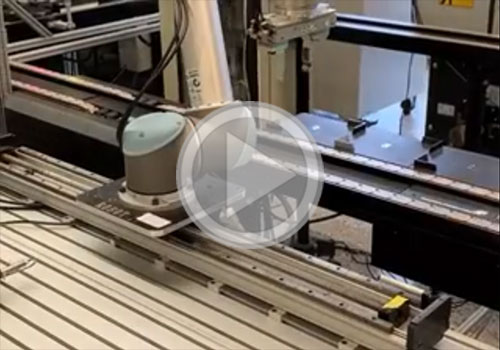

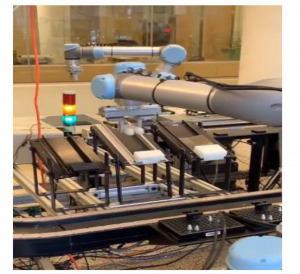

CIM integrated the use of: Collaborative Robots programmed with different pathways for the operation. Vision system programmed to identify the working parts. CNC to cut-off the working pieces.

Collaborative Robot Tending