AUTOMATED HOT-WHEELS PARKING SYSTEM

For this project we were given, 25 mm x 25 mm 8020 aluminum extrusion, stepper motors, and the belts and pulleys. The goal was to design a product that controlled axis motion for a system and whose part were 3D printed. Our team built a automated parking system for toy cars.

Collaborators: Adrian Perez, Jose Tejeira, Ignacio Fimbrez, Mackson Li

Results

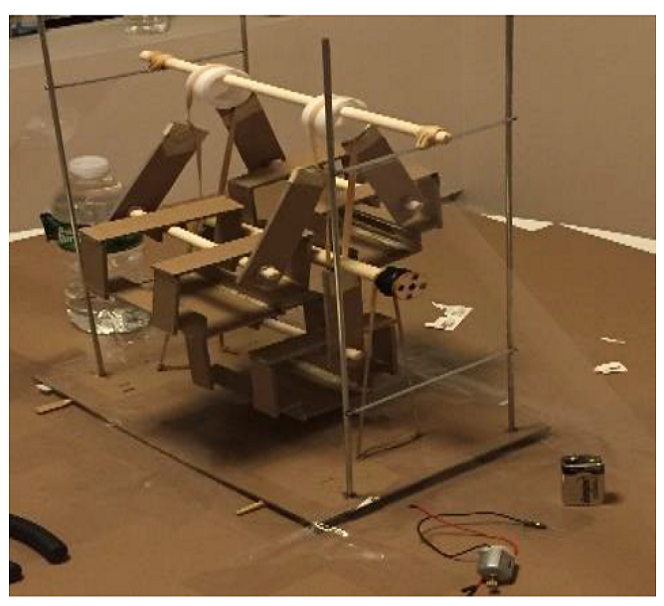

We succeeded in building a system that is small and lightweight, so that it can be easily disassembled and carried in a backpack. All parts were modeled using SolidWorks. Learned how to use 3D slicer software and how to orient parts correctly for optimal printing. Coded Arduino UNO to allow user input. The computer prompts a message asking the position of the toy car and the motors move to the desired location to either park or retrieve a vehicle. The aluminum extrusion served as both structural material and linear guide. It improved the quality and effectiveness of my former design attempted in my freshman year (see image below):

Freshman Prototype

3D Slicer Software

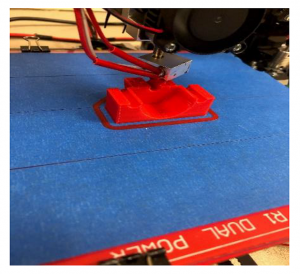

3D Printed Component

3D Printing Components