GASKET DESIGN

The intention of this project was to be exposed to some of the basic skills needed to manufacture mechanical components. I was asked to produce a gasket that fits on top of a aluminum block, allowing unrestricted access to all of its features.

During this project I learned to make accurate measurements of the features of a mechanical component, to produce dimensioned sketches that serve as a basis for the creation of a CAD model, and to use of the GibbsCAM software for the manufacture of machine components on a CNC mill.

Sketches

Materials:

• Aluminum block with several machine features

• 1/16″ – thick PVC

The measurements were made using a calliper

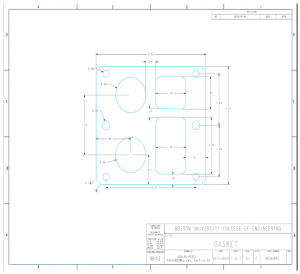

The part associated with this technical drawing was imported to the GibbsCAM software, and it produced the required G-code for the CNC mill.

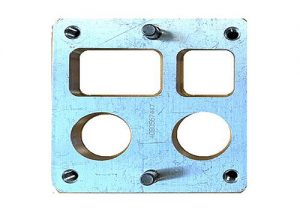

A stock of 1/16″- thick PVC was mounted inside the CNC, using double sided tape to hold the piece in place. Next, the Gcode file was loaded onto the Mill and the gasket was machined.

Technical Drawing

Assembly & Results

As it can be seen in the final product, the gasket fits correctly onto the aluminum. However, we can notice the gasket partially obstructing the threaded holes. Note that when the measurement were initially taken, the distance from the pin to the hole was from the outer diameters and not form center to center, or inside diameters. The reason of this misalignment is due to the fact that when producing the CAD drawing, I accounted for the pin radius, instead of the diameter, causing the holes to be shifted to the sides.