AUTOMATED BEAD STRINGING MACHINE – SENIOR CAPSTONE

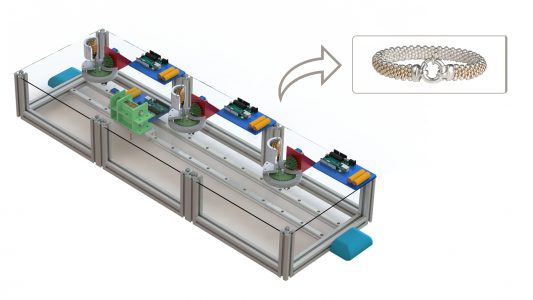

For this project, my team will be working for Dovera Design, a company that specializes in the design and creation of custom jewelry. They want to expand but are limited by the amount of jewelry they can deliver. The entire manufacturing process is done manually and therefore difficult to scale. Another limitation for expansion is the continuous loss of beads by human error. For those reasons, Dovera Designs wishes the development of a device to automate part of the jewelry making process; more specifically, the stringing and sequencing operation required for the manufacture of bracelets.

Collaborators: Adrian Perez, Darwin Chiu, Eva Gee, Yash Majithia, Kristy Guo

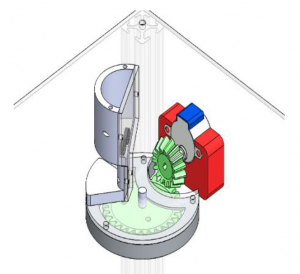

Dispensing Mechanism –Top section

• Hopper storages beads and they fall through the funnel.

• Vibrating Motors avoid beads getting stuck in the funnel.

• Stepper Motor drives bevel gears with holes that fit one bead at the time.

• SolidWorks used to design parts, create assembly and generate exploded view.

Bead Dispensing Mechanism

Exploded view of the Mechanism

Collecting Mechanism – Middle section

• Alternating motion of vice jaws is necessary for the needle to stay in place.

• First Design had one moving and one fixed jaw. The beads need both jaws to open for it to fall.

• Currently manufacturing a Bidirectional Lead to move both jaws.

• SolidWorks used to design parts, and create animations that demonstrate how vice jaws move and how bead falls.

Bead Collecting Mechanism

Bidirectional lead to open and close the vise

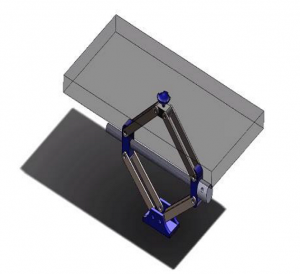

Lifting Mechanism – Bottom section

• Entire system rest upon this mechanism.

• Needle needs to move up to catch beads.

• Currently working on two different solutions: one based on a scissor lift and the other on a carjack.

• SolidWorks used to design parts, and create animations that demonstrate vertical range of motion

Lifting Mechanism #1